Although they may look insignificant and be the least expensive part of a vehicle’s steering and suspension system, bushes are in fact crucial to its performance and safety. Nowhere is this more so than the bushes that are used in suspension arms, which will also have a huge effect on the longevity of the complete unit.

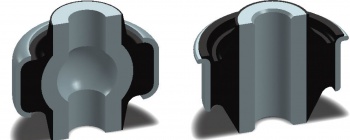

First Line does not compromise with the quality of its components and bushes are no exception as it only follows the original equipment (OE) standard. Unfortunately not all suppliers follow this policy: instead they offer cheaper, non-OE standard bushes that can sometimes use a straight tube in their construction, rather than OE standard swaged tubes.

Swaged tube provides a greater bonding area for the rubber, which directly increases the longevity of the bush. Although swaging is an extra step in the manufacturing process and therefore an extra cost, the benefits of this process are all too plain to see when the cheaper bush fails earlier than expected.

Workshops need to be able to trust the components they fit, and only quality suppliers like First Line can provide that level of faith. First Line has done all the hard work in ensuring their products meet the highest standards, which means that factors can specify and technicians can fit them with complete confidence. These matters are all about quality, not about the price.

If a replacement bush is poorly manufactured or manufactured to an inadequate specification, it is highly likely not to possess the correct shore hardness or deflection attributes that are required and will have an adverse effect on the handling performance/ride quality of the vehicle. The vehicle will pull or lurch in one direction or the other as it is driven. Even if low quality bushes are replaced as a pair, the vehicle will not perform as it is designed to and is likely to feel dull and unresponsive to the driver.

Unfortunately, as well as poor quality components, the First Line technical team quite often encounter wishbones that have bushes that have failed prematurely due to their incorrect fitment. It is worth noting that in most cases the correct specialist equipment is required for the removal and fitment of many steering and suspension parts, including wishbone bushes! These procedures should always be followed up with a full wheel alignment check.

A wishbone should only have the fitting bolts tightened up when the vehicles wheels and axles are in the normal ride height position. Not, as some garages do, when the wheels are in an unloaded ‘hanging’ position. Doing this will put a torque reaction on the wishbone bushes when the vehicle is taken off the service ramp, which will lead to premature failure of the wishbone and the centre of the wishbone bush will have been ripped away.

There is also an increasing trend to use stiffer polyurethane ‘competition’ style bushes for general road going cars. The instant benefit for the driver is an increased sensitivity in the vehicle’s handling characteristics. However, the harder compound used in these bushes will put extra load on to ancillary steering and suspension components that is contrary to the vehicle’s original design and will lead to premature failure of components such as anti-roll bars and wishbone bush mountings etc.

For more information about the quality products in both the First Line and Borg & Beck range, please call the sales team on: 01869 248484 or visit: www.firstline.co.uk

Click here to open the navigation menu

Click here to open the navigation menu