Pierburg explains why it believes Original Equipment to be superior to compatible alternatives. Fuel pumps manufactured in Mexico and China were tested in the Pierburg laboratory. Both pumps were tested for functionality and were subject to a 500 hour durability test. These tests were designed to assess whether the pumps were up to the rigorous demands a modern vehicle puts on the fuel system. Following these tests, the units were compared to the equivalent Pierburg part to see how they measured up.

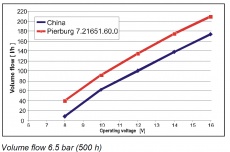

The Chinese pump was very unstable and noisy, becoming worse as the pressure increased. When the power consumption hit 19 amps the pump temporarily broke down.

At the end of testing, the required flow rate could not be reached – in fact the flow rate was approximately 35% less than the Pierburg equivalent. If a fuel pump doesn’t hit the required flow rate this can lead to engine misfire and problems with starting the vehicle.

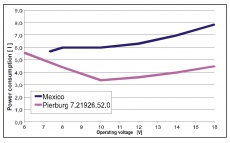

The Mexican pump failed to match the efficiency of its Pierburg equivalent - It displayed considerably higher power consumption than the OE part. Parts that require more energy are less economical – the more power required, the higher the fuel consumption of the engine.

Click here to open the navigation menu

Click here to open the navigation menu